News

News

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

Industry News

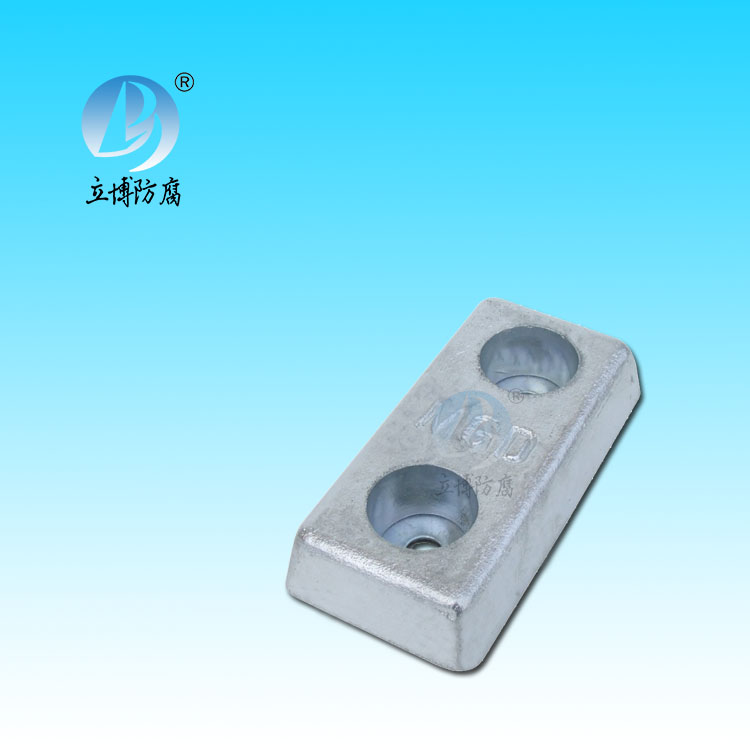

Series magnesium alloy sacrificial anode style

- Author:Libo

- Source:wphotodu.cn

- Date:2021-06-11

- Click:0

Implementation standard:

Sacrifice anode for magnesium alloy

Main uses:

Magnesium alloy sacrifice anode is suitable for underground and fresh water oil, gas, water supply and drainage pipeline, underground cable, chemical industry, communication, harbor, ship, reservoir gate and other engineering anti-corrosion protection.

Product features:

The magnesium alloy produced by our company is made of high quality raw materials. The anode potential is negative and the quantity of electricity generated per unit mass is large. It is an ideal sacrificial anode material. Suitable for cathodic protection of metal structures in soil, fresh water and seawater, such as oil and gas pipelines, storage tanks, hot water exchangers, condensers and so on.

Magnesium alloy sacrifice anodes are produced according to the national standard GB/T17731-2004 "Magnesium alloy Sacrifice Anodes", and the anodes used for pipelines are also in line with SY/T0019-97 "Design Code for Cathodic Protection of Sacrifice Anodes for Buried Steel Pipelines".

The product has the following characteristics :(1) small specific gravity, negative potential, (2) high driving voltage to iron, low current efficiency, (3) especially suitable for high resistivity medium.

(Banded magnesium anode is recommended for resistivity greater than 100 ω ·m)

Precautions for use:

Collision with steel structure should be avoided.

When used in soil, it should be buried in a low, wet place.

When used in soil, the anode must be buried in a packing bag.

During installation, the distance between the pipe and the anode and the distance between the anode and the anode should be greater than or equal to three meters, and the minimum should not be less than 0.3m.

After the anode is placed in the soil pit in dry areas, the packing material should be fully soaked with water before backfilling the soil, lest the anode cannot conduct electricity adequately.

客服QQ

客服QQ