News

News

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

Industry News

How to do cathodic protection of buried pipeline

- Author:Libo

- Source:wphotodu.cn

- Date:2021-08-05

- Click:0

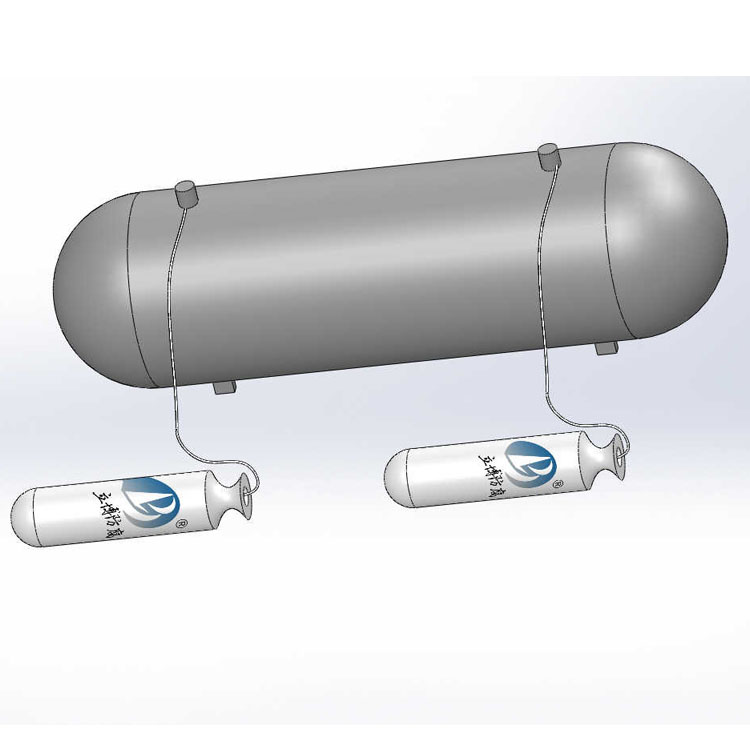

There are anode and cathode areas on the surface of the metal pipeline buried in the soil. How to do cathodic protection of the buried pipeline? Local corrosion occurs in the anode area. The protected metal pipe has a good anticorrosive insulation layer, which reduces the cost of cathodic protection. According to the way of protection current, cathodic protection can be divided into sacrificial anode and forced current protection.

The main advantages of sacrifical-anode method are no external power supply, less external interference, low installation and maintenance cost, no land expropriation to occupy other buildings and structures, high utilization of protection current, and more suitable for corrosion of buried steel pipelines in cities.

The combination of anticorrosive insulation and cathodic protection is the most economical and reasonable anticorrosive measure, because the anticorrosive coating cannot be guaranteed to be destroyed during production, transportation and construction. Perfect isolation of pipes from corrosive environments and media is therefore impossible. How to do the cathodic protection of buried pipelines? Various materials used for anticorrosion and insulation have different degrees of water absorption and air permeability. Therefore, under the action of soil solution, the buried soil will gradually absorb water and age.

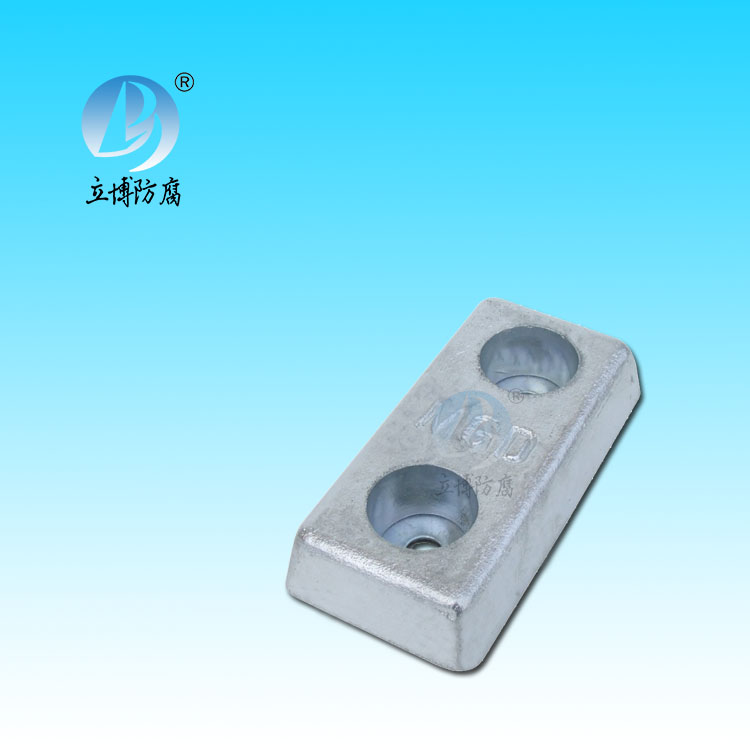

Construction requirements of sacrificial anode:

(1) The burying of the anode: according to the proportion of preparation, well mixed packing, into φ300×1000 cotton or hemp bag, after using iron sand paper polishing and surface cleaning treatment of the anode in time inserted into the center of the packing, and compacted; Wrap the package with iron wire and tie it firmly, and bury it horizontally or vertically at a distance of 2-3 meters on the side of the pipeline. The buried depth should be the same as that of the pipeline. Below the freezing line, the concrete should be backfilled after being watered by layers with fine raw soil mixed with salt.

(2) All cables and anode, copper nose, pipe, strengthening plate connection with tin welding (except the connection in the distribution box), before welding to peel off the anti-corrosion insulation layer, clean, polished welding place; The welding place and the bare part of the cable must be treated with insulation and anti-corrosion; The cable and PVC protective sleeve are loosely and naturally buried, the buried depth is the same as that of the pipeline.

(3) The cable in the protective cover should have a 0.8m redundant length (the redundant part of the cable does not add PVC protection sleeve), in order to put the distribution box to the ground detection parameters; The two outlet holes of the distribution box should be filled with bitumen soaked hemp wire, and then filled with bitumen for waterproof treatment.

(4) The color of the cable connecting the pipeline should be separated from the color of other cables, so as to identify and detect.

(5) After the construction, installation and testing of the cable box, the cover of the cable box shall be tightened and waterproof.

客服QQ

客服QQ