News

News

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

Company News

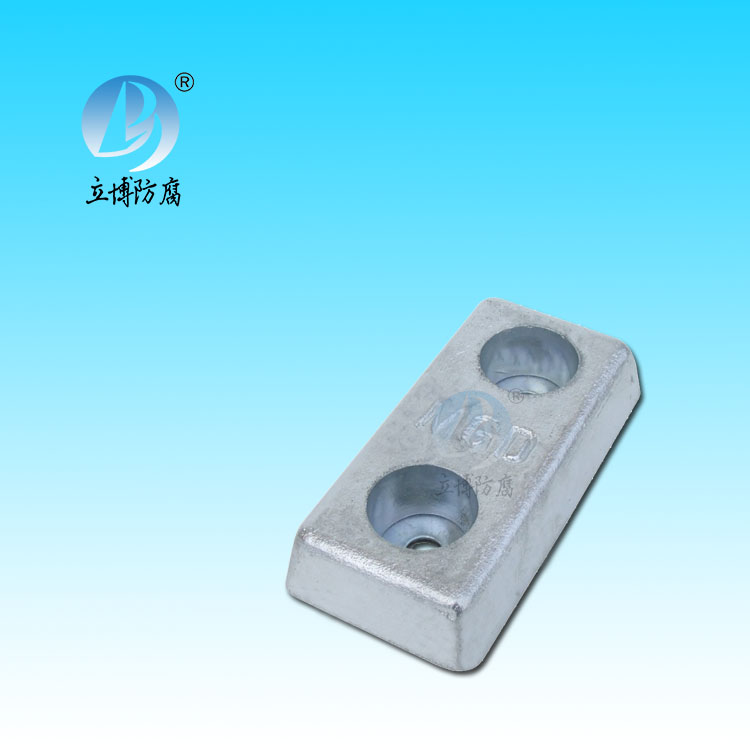

Contact cast magnesium alloy

- Author:Libo

- Source:wphotodu.cn

- Date:2021-06-11

- Click:0

In thixotropic forging, the prepared non-dendrite bars are quantitatively cut and reheated to the liquid-solid two-phase region (the volume fraction of solid phase is 50%-80%), and then die casting or die forging process is used for semi-solid forming. The thixotropic forging does not use melting equipment, and the ingot material is easy to be transported and heated after reheating, and easy to realize automation. However, the preparation of precast billet requires huge investment, and the hub technology is monopolized by a few foreign companies, resulting in its high cost, only suitable for the manufacture of high strength hub parts. Among them, 75.5% aluminum die castings and only 1% magnesium die castings.

客服QQ

客服QQ